O-ring failure can be caused by a variety of factors. In this blog, we’ll focus on three of the major areas which can lead to O-rings failing:

-

- Material selection

- Hardness

- Assembly

Select the right material for the application

The choice of material should be ruled by how it performs in tough and demanding applications. Using EPDM with oil, or FKM at extreme low temperatures will not deliver the required results. Selecting the wrong material, particularly in critical applications involving hazardous materials or extreme temperatures, can endanger both lives and property. Some industries, such as the medical or food industry, have stringent requirements to ensure hygiene as well as safety. Before selecting a material, or changing from one material to another, review its chemical compatibility and check our material selection guide.

Ensure correct hardness based on the planned pressure

The hardness (DH) of flexible rubber materials is the measurement of its resistance to permanent indentation and should be determined by the amount of pressure the O-ring will be subjected to. Softer materials flow more easily into the mating parts, such as glands, bores, rods and flanges, while harder materials offer greater resistance to extrusion. When selecting a material, refer to our handy chart of typical usage and hardness , which allows you to determine the right material for your application.

Prevent damage during assembly

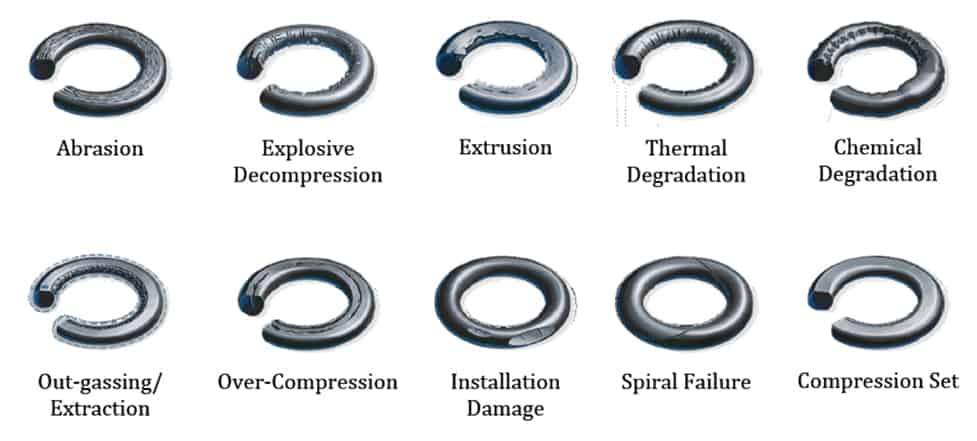

O-rings can be sheared, nicked, cut, torn, twisted, turned & overstretched during installation which may cause leakage and even damage to parts. To prevent this from happening, make sure the O-ring conforms to the required dimensions. To avoid spiral failure, slide the O-ring into place (don’t roll it). Avoid overstretching. Use lubricant and cover threaded parts which might tear the O-ring. Avoid sharp edges on glands or components. And finally, don’t use excessive force.

Other factors that may cause failure include:

Compression set ensure that the compression or squeeze is not excessive, as this will cause breakdown of the molecular structure. |

Abrasion avoid frictional heat buildup either due to rough surfaces on the groove or the O-ring, especially at the seal interface. |

Excess swelling check that any chemicals that come into contact with the sealing material do not cause the O-ring to swell excessively. |

Fluid incompatibility if the O-ring swells, shrinks or shows signs of chemical attack, it could be caused by fluid incompatibility. |

These are just a few of the reasons O-rings and gaskets may fail. We’ll be featuring common problems and solutions on our social media channels, so follow us to make sure your O-rings perform to expectations!