Rubber / Elastomer

What is Rubber?

Originally, the term rubber was used to refer to compounds produced from a substance called latex found naturally in the Hevea tree. The chemical name of this polymer is polyisoprene. Natural rubber possesses many excellent physical properties including high resilience, high tensile strength, good abrasion resistance, and is extremely waterproof.

What is an Elastomer?

As the term rubber is used to describe compounds produced from materials that are found in nature; the term elastomer is used for materials that are produced synthetically and exhibit elastic properties. Today the terms rubber and elastomer are often used interchangeably.

A definition of a rubber compound or elastomer is: ‘Any material that can stretch to at least 100% of its original length, and return to its original shape without permanent deformation’.

An elastomer is a polymer with viscoelasticity, often using carbon, hydrogen, oxygen, or silicon.

Rubber Production:

All rubber / elastomer compounds are created through the combination of specific ingrediants. The types of ingrediants used are:

- Polymer: The elastomer is the main component and the starting point in determining the basic heat and chemical resistance properties.

- Plasticizer: Improves low-temperature properties, and helps in the mixing and molding process.

- Reinforcing Filler: Usually Carbon Black, for strength.

- Antioxidant: Counteracts deterioration.

- Other (e.g. Curative, Accelerator, Lubricant, or Scorch Retarder)

Vulcanization:

Vulcanization, also called curing, is a chemical process for modifying polymeric chains of rubber or elastomers into more durable materials via the addition of curatives or accelerators, usually sulfur. These additives form cross-links between the individual polymer chains, resulting in vulcanized rubber materials that have enhanced physical properties.

General Properties of Elastomers:

Elastomers are classified and categorized by various phsyical properties. Some of the most common properties are as follows:

- Compression Set: The permanent deformation that remains when an applied force is subsequently removed.

- Hardness: The measurement of resistance to permanent indentation.

- Modulus: The tendency of an object to deform along an axis when opposing forces are applied along that axis.

- Tensile Strength: The maximum stress that a material can withstand while being stretched or pulled before failing or breaking.

- Elongation: The length at breaking point expressed as a percentage of the original length.

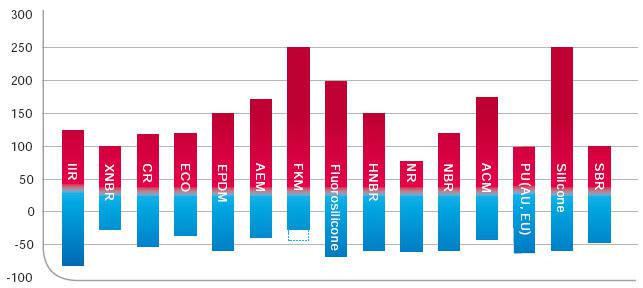

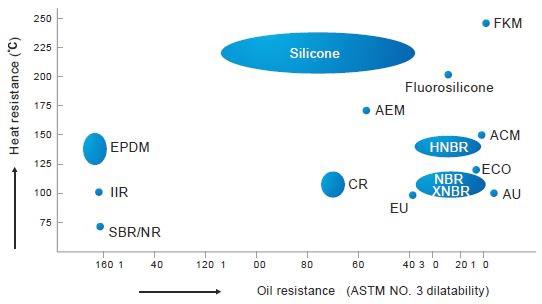

Service Temperatures

The service temperature of an elastomer is important to understand how it will react at different temperatures. This service temperature range chart is for reference only. In an actual service environment, compounds may not reach the maximum temperature as indicated in this chart. However, a higher temperature may be attained if exposure is for a short period or is intermittent.