Ensuring Durability and Precision in Military Applications

Introduction: Meeting the High-Stakes Demands of the Military Sector

In the demanding and dynamic environment of the military market, selecting the right materials and components is crucial. These materials must withstand extreme conditions (including extreme high/low temperatures, aggressive chemicals, oils, etc.) and perform reliably under stress. This requires a specialized approach to material development and production, focusing on durability, precision, and compliance with rigorous military standards. Therefore, the importance of high-quality elastomers and rubber products cannot be overstated, as they play a vital role in various military applications.

Application of Seals in the Military Sector

In the Military industry, a diverse array of elastomer and rubber products are utilized to fulfill various critical requirements:

• Various types of elastomer seals, including o-rings, covers, diaphragms, and grommets are essential. These find applications in door, and galley, as well as in fuel and hydraulic systems, and control surfaces. Additionally, we specialize in gaskets for military vehicle filters, system filters, and various types of seals such as battery seals, dust cover seals, objective cover seals, door gaskets, seals for optical devices, and bonded rubber parts.

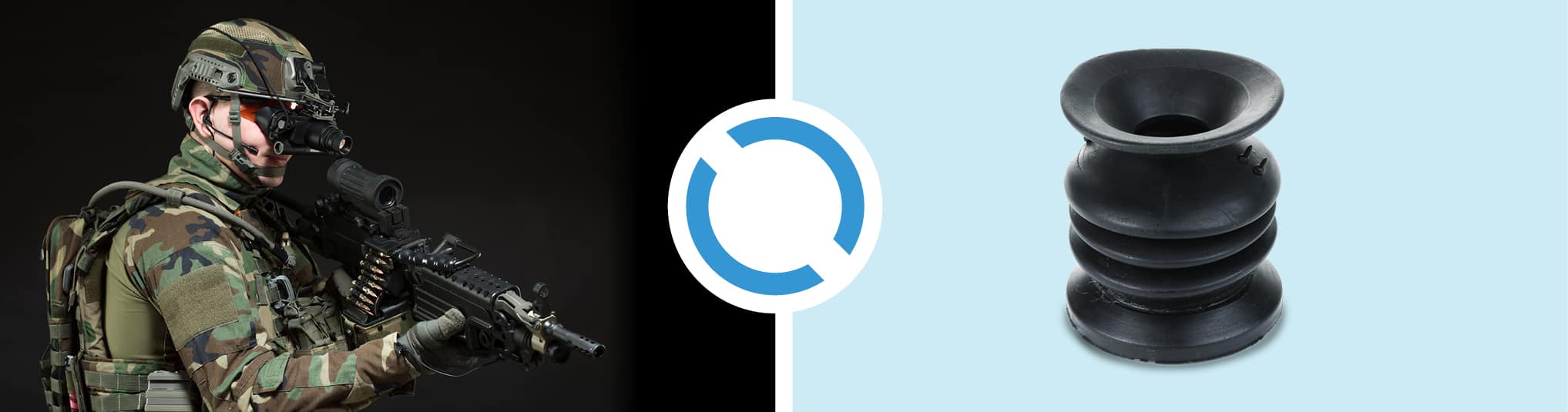

• Custom-shaped molded parts, including eye guards, objective covers, protective covers, control surfaces, and antennas for communication devices, as well as rubber mats and pads, play vital roles in various applications. Specialized materials are employed, such as erosion-resistant elastomer coatings, and gas-resistant compounds (such as mustard gas), which are crucial for protecting various components and users.

Among our clients, you can find leading manufacturers in the field Environmental Protection for Vehicles & Mobile Shelters, Electro-optical and Optical Sight devices, blast protection valves for Critical Infrastructures, and air treatment products. We also provide seals for complex communication systems used in the modern battlespace, as well as for high-tech companies in the defense and homeland security sectors. Our process often begins with receiving a drawing, after which our engineering team works in tandem with the customer’s engineer to devise the best solution tailored to the unique challenges presented by the final device.

Ensuring Safety and Performance: The Critical Role of UL/Flammability Standard

The importance of UL (Underwriters Laboratories)/flammability ratings in elastomer and rubber products for military applications cannot be overstated. In the military context, materials are often exposed to extreme conditions, including high temperatures and potential fire hazards. The UL rating system provides a standardized measure of how materials behave under fire exposure, which is crucial for ensuring the safety and effectiveness of military equipment.

Elastomers and rubber materials are widely used in various military applications such as seals, gaskets, hoses, and protective coatings due to their flexibility, durability, and resistance to extreme environments. However, their inherent flammability can pose significant risks. By adhering to strict UL flammability standards, like UL94 and UL157, manufacturers can guarantee that these materials will not only perform reliably under normal conditions but also offer critical fire resistance. This ensures that military equipment remains functional and safe in the event of a fire, thus protecting the lives of service members and maintaining the integrity of critical missions. Therefore, the UL/flammability rating of elastomers and rubber products is a key factor in the material selection and design process for military applications, balancing performance requirements with essential safety considerations.

Techno Ad’s Contribution to Military Needs

Techno Ad specializes in supplying a wide array of elastomer and rubber products tailored to the specific needs of the military sector. Our product range includes NEOPRENE, SILICONE, NBR – in various levels of hardness and color, and other rubber materials such as EPDM, FKM/VITON®, FLUOROSILICONE. Each is chosen for its unique properties and suitability for various military applications. These materials are used in making essential components like seals, gaskets, hoses, and protective coatings. By focusing on these specialized materials, Techno Ad ensures that each product is optimally designed for its intended use, providing the reliability and performance required in military operations.

Customization and Compliance: The Key to Meeting Military Needs

Understanding the unique requirements of the military sector, Techno Ad emphasizes the importance of customization and compliance. Not every elastomer or rubber product is suitable for every military application. For example, mat surface finish is often required to avoid reflection and “blur” visibility. Therefore, it is essential to state specific needs and standards in the request process. This approach enables Techno Ad to provide precise and compliant solutions, ensuring that each product not only aligns with but also enhances the performance of military equipment.

Leading Standards and Quality

By clearly communicating its capability to supply MIL-STD (Military Standard) compliant products and its partnership with the reputable supplier Parker Hannifin, Techno Ad positions itself as a reliable and innovative provider in this sector. Parker O-Ring & Engineered Seals Division is renowned worldwide as a Qualified Products List (QPL) manufacturer and provider of MIL-Spec. Techno Ad’s efforts are aimed at reinforcing its reputation as a leader in the field, capable of meeting the high standards and evolving needs of military applications.

Navigating Military Challenges and Offering O-Ring and Seals

Techno Ad believes in the power of collaboration. Working closely with defense organizations, technical experts, and end-users, we are able to gain valuable insights into the real-world demands and challenges of military applications. This collaborative approach fuels innovation, leading to the development of products that are highly functional in demanding military environments.

Staying Ahead in a Rapidly Evolving Landscape

The increasing demand of the military and the defense market requires constant adaptation and advancement. As technologies and processes advance, it’s imperative for our manufacturing methods and quality assurance systems to be in a state of continuous evolution. This commitment is not just a challenge; it’s a necessity to guarantee the reliability and durability of each product we craft.

Our military products are destined for environments and applications where reliability isn’t just desired, it’s demanded. These severe conditions require products that are nothing short of dependable. Therefore, we dedicate considerable time and effort to production, ensuring that our production process not only meets but exceeds the stringent requirements of a high-compliance industry. This dedication is what sets our military-grade products apart, ensuring they perform exceptionally, even under the most challenging conditions.

Conclusion: Techno Ad’s Enduring Dedication to Military Excellence

Techno Ad’s extended commitment to providing superior elastomer and rubber products for the military sector reflects its understanding of the industry’s demands and its willingness to meet these challenges head-on. Our comprehensive approach, from adhering to stringent military specifications to fostering innovation through collaboration, positions us as a key partner in the defense industry. As we continue to evolve and adapt to the changing landscape of military technology, Techno Ad remains dedicated to excellence, ensuring we meet the needs of today’s military and anticipate those of tomorrow.

For further details on our products and services, and to see how we can meet your specific military application needs, contact us here.