What is adhesion?

In our everyday life, we all know and use adhesive materials like glue, tape, and stickers. However, the concept of adhesion is not easy to understand. Adhesion is the force that keeps two dissimilar surfaces in contact with each other.

Adhesion occurs when one material clings to a different material at the molecular level. This is the first property needed to create an adhesive material.

The second property needed is cohesion, which occurs when identical molecules (molecules of the same material) cling to one another.

Cohesion is the strength of the adhesive that helps it withstand external forces without breaking. Adhesion is required to bond two different materials to each other and cohesion is required so the adhesive itself holds up and does not break.

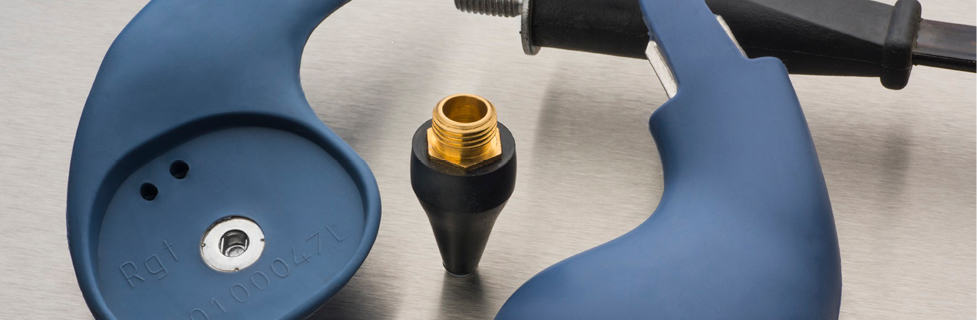

Bonding rubber-to-metal creates an extremely strong and durable material.

Metal-bonded rubber has many applications in various industries, including waterworks, agriculture, healthcare and medical devices.

Creating a quality rubber-to-metal bonded part is a complex process that requires specific knowledge. This article overviews the requirements for a quality bonding process

Choosing the right adhesive

Adhesives for rubber-to-metal bonding require specific properties, depending on the types of metal and rubber involved in the bonding process. Other factors include drying temperature, storage conditions, and the recommended time frame for applying each adhesive coating. Some adhesives are used for the first coat and some are best for the second coat; others are used as a primer to bond the adhesive to the surface.

The rubber-to-metal bonding process

Preparing a successful rubber-to-metal bond consists of five important steps:

1. Preparing the surface

2. Priming the parts (optional)

3. Applying the adhesive

4. Molding

5. Testing to ensure a quality bond

Each step is critical in creating a successful rubber-to-metal bond. Let’s go over each step.

Preparing the surface for adhesive bonding

This is a key step in creating a successful bond because oils and other residues prevent full contact between surfaces and adhesives, which degrades the quality of the adhesion. The process of preparing a metal surface for adhesion must include the cleaning and removal of all oils or other deposits from the surface. It is also important to scrape and remove any existing coating.

To remove the oil and grease, it is recommended to use a degreasing solvent or clean the surface with an alkaline solution. For materials that cannot be dissolved, such as rust, it is recommended to use a mechanical treatment method such as grit blasting, abrading, or machining. Since rough surfaces bond better than smooth surfaces, sandblasting is recommended to roughen smooth surfaces

Applying the adhesive

After the surface is prepared, the adhesive should be applied carefully, following the manufacturer’s instructions. The adhesive must be applied in an even layer to avoid air bubbles. In addition, masking is needed to cover everything except the specific area where the rubber will be bonded.

Sometimes a primer layer is needed to enhance the adhesion, depending on the chosen adhesive and the types of rubber and metal to be bonded. The role of adhesive primers is to protect the surface of a material that has to be bonded at a later stage.

Molding

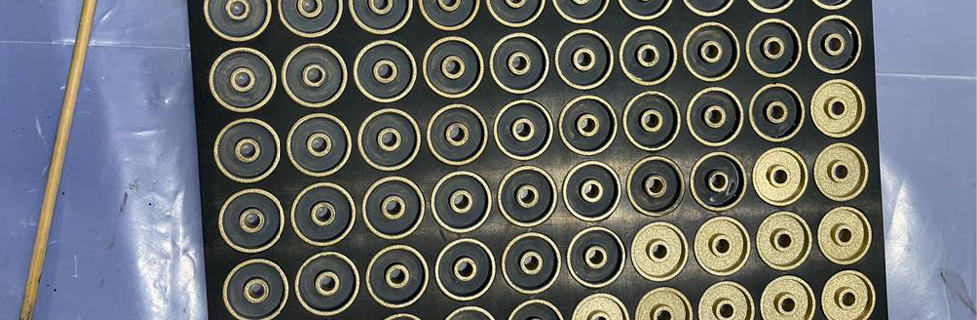

To combine the adhesive-coated metal and rubber compound, the parts are molded together. The prepared metal surface is inserted into a mold cavity and treated under certain conditions (pressure, time, and temperature).

The two common methods for molding rubber to metal are transfer molding and injection molding. In transfer molding, the metal parts are inserted into a heated mold and solid rubber is put into the mold using a heated plunger.

The rubber compound is cured and vulcanized at high pressure and temperature. In injection molding, again, a metal part is inserted into the mold, but here, the rubber is liquid and injected into the mold.

Injection molding is quicker and more precise than transfer molding. However, transfer molding also has its benefits. It requires less expensive equipment and is suitable for complex shapes.

Testing

After production, testing is conducted to examine the strength of the bond and to identify any cases of adhesion failure. There are various methods for testing the quality of the adhesion.

At Techno Ad, we match the relevant test methods to the product and the type of bonding.

Which solution is right for you?

Techno Ad has the expertise to create the best rubber-to-metal bonding solution.

Contact us today, and we’d be happy to help!