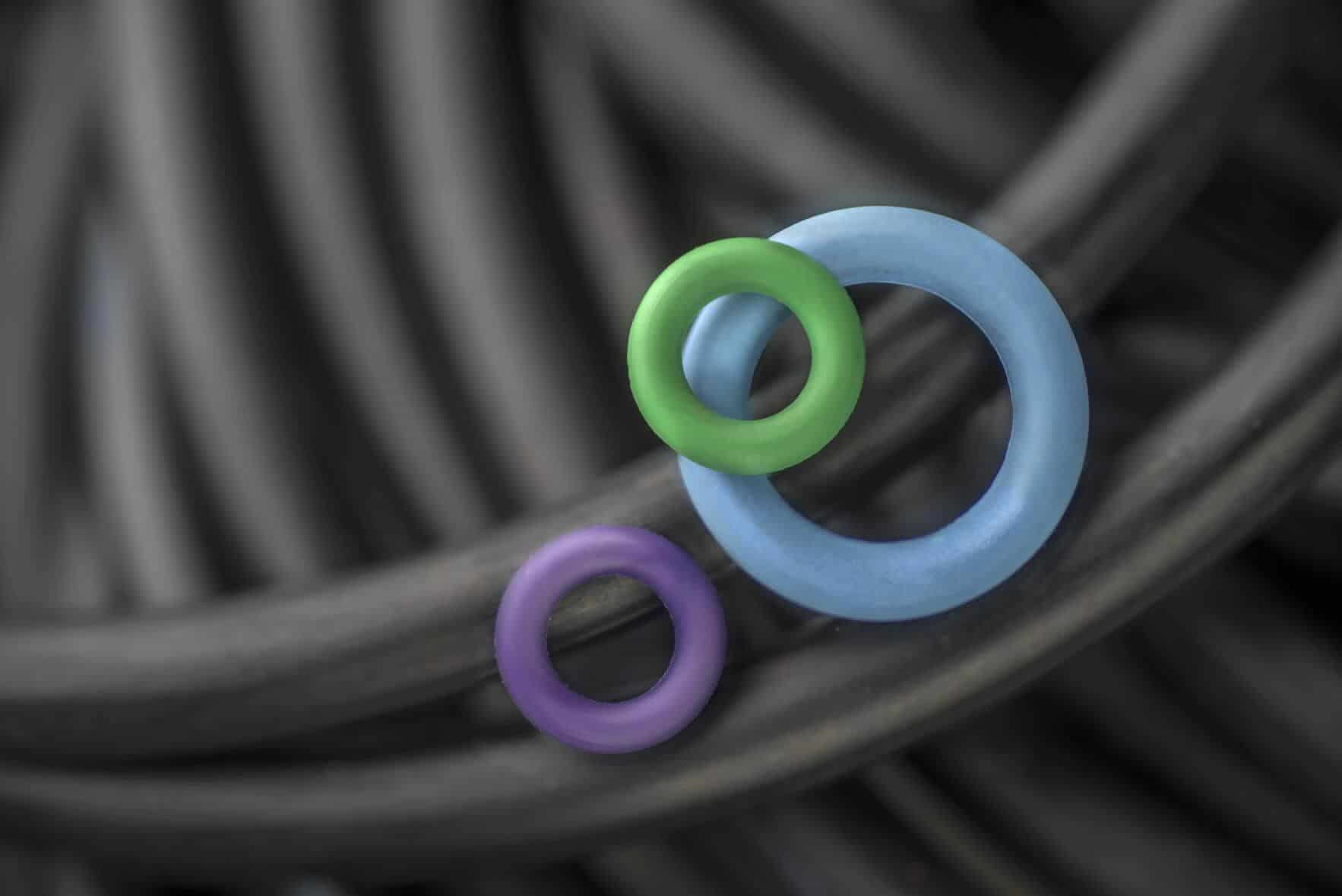

Failure of the O-ring due to leakage is one of the most common causes of a shorter than expected life-time ! How can this be avoided ?

There are many mechanical tests that manufacturers use to differentiate the benefits of various fluoroelastomer compounds. One such property is compression set but there are others such as stress relaxation, leak testing or outgassing.

How do you measure compression set ?

- A sample of the compound (either a specially molded pellet or O-ring) is compressed in a specifically made jig for a predetermined amount of time at a specific temperature (always mentioned in the test conditions) in an oven which maybe specifically adapted with recirculated air or nitrogen. There are a range of various international test conditions such as ASTM D395 which would give the exact test method used. The sample is removed from the oven allowed to cool for a predetermined time and then the thickness is measured and compared versus the original thickness as a percentage.

What do the compression set numbers mean ?

- The lower the number the better is the compression set

How best to ensure that the material selected has the best compression set?

- Ensure that the temperature used for the compression set is in line with that used in the function of the seal as a higher temperature may rise to other effects of the material.

- Ensure that the material and compound are selected have the lowest set and that the vulcanization and post-cure (if applicable) have been optimized to give the lowest compression set. Some times a further post cure maybe advantageous to improve certain mechanical properties such as outgassing.

- If in doubt call your Techno Ad sales or technical contact.

What other factors need to be taken into account to avoid leakage?

- Ensure that the O-ring is inserted correctly into the groove as twisting of the O-ring can also cause premature failure due to leakage.

- Check that the O-ring is the correct size for the groove not forgetting that each material has a different Coefficient of Thermal Expansion (C.T.E.) so the same size may not be suitable for different materials such as Nitrile (NBR) or Fluoroelastomer (FKM)..

- Ensure that the compression or squeeze is not excessive on the O-ring as this will cause breakdown of the molecular structure.

- Avoid frictional heat build up either due to rough surfaces on the groove or the O-ring especially at the seal interface.

- Check that any chemicals that come into contact with the sealing material do not cause the O-ring to swell excessively.

- When leakage is suspected of the O-ring ensure that the leakage is really happening rather than either outgassing (which is not uncommon in fluoroelastomers) or that in the case of helium testing the gas is not just dissolving into the polymer matrix and then passing thru the material (again not uncommon in fluorelastomers or perfluoroelastomers).

- Again if in doubt contact Techno Ad for further help and information.