The mechanical properties of the material

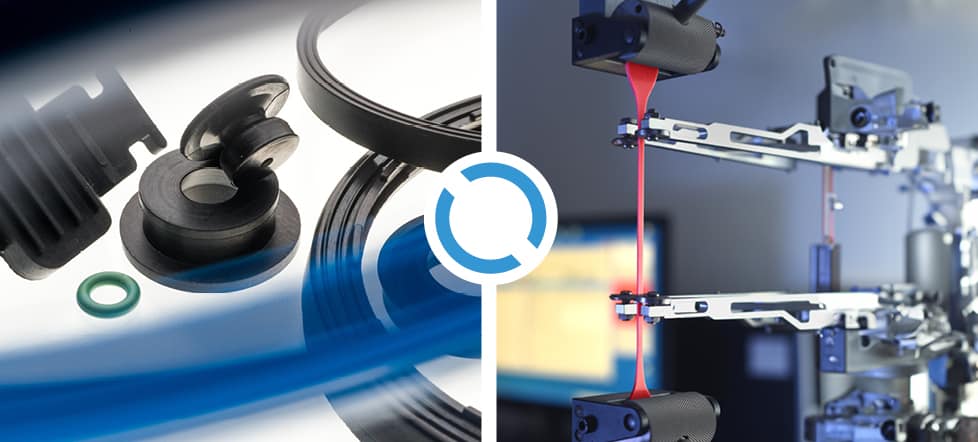

When choosing an elastomer for a sealing solution, it is crucial to consider the mechanical properties of the material. These key properties generally include the tensile strength and elongation at the breaking point of each material. By testing an elastomer’s properties, we can determine its quality. In this blog, we will examine three mechanical properties that serve as qualifying criteria for elastomers and why they are relevant to elastomers and sealing solutions.

Tensile Strength

The tensile strength of a material refers to the amount of stress (stretching force per unit area) a material can take before breaking. Beyond this point, the material can no longer maintain its structural integrity, leading to rupture or tearing. Given the extensive elasticity of elastomers, they can often withstand stress before reaching this point. Essentially, the breaking strength of an elastomer offers a key insight into the material’s ultimate deformation point.

Testing the tensile strength of an elastomer is crucial in applications such as sealing solutions, where elastomers must be flexible and resilient, enduring various stresses and strains without failing. Tensile strength is measured in megapascals (MPa) or PSI, similar to the measurement unit used for tensile stress. To measure the tensile strength of a material, a small sample with a fixed cross-sectional area is taken and stretched with a device called a tensometer, at a constant strain rate, until it breaks.

The ASTM (formerly the American Society for Testing Materials, currently ASTM International), specifies two standard testing methods and their results may differ: dumbbell and straight-section specimens or cut-ring specimens. In the first method, the test specimens are injection-molded or cut from a flat sheet. In the second method, an O-ring specimen is cut and progressively stretched until it tears, thereby determining the material’s breaking strength

Elongation

As indicated by its name, elongation is the process of stretching a material. When force is applied to an elastic material, the material changes length. The material can either elongate or compress, depending on the type of force. If the elongation is negative, the final length is less than the original, meaning that the material has compressed instead of elongated.

Elongation is defined as the ratio of change in length to the original length and is expressed in percentage terms. Ultimate elongation is the percentage change in length from the original length (length at rest) to the length at the breaking point. When a rubber specimen reaches twice its length before breaking, its elongation percentage is 100%.

Elongation is tested using an extensometer – a device which measures the change in length of a material under stress. An extensometer is usually integrated with a tensometer, thereby allowing both properties to be measured at the same time.

Modulus

Using terminology specific to rubber elastomers, “modulus” refers to the stress at a predetermined point of elongation, generally at 100%. It is measured in pounds per square inch (PSI) or MPa (Megapascals), essentially representing the material’s elastic modulus.

A compound with a higher modulus is more resilient when it comes to bouncing back from peak overload or localized force, and its resistance to extrusion is more effective. As hardness increases, typically so does the modulus. It is most likely the best overall indicator that represents the strength of a specific compound, assuming other factors remain equal.

While these three baseline properties are important, they are not the only factors to consider when evaluating the future functionality of a rubber elastomer. During their life cycle, rubber components are subjected to forces that can cause deformation. They are often exposed to extreme temperatures and aggressive chemicals. Given that rubber is an elastomer, its uses frequently require it to be stretched, compressed, and even twisted. The true testament to a rubber elastomer’s quality is its ability to maintain integrity and function under all these varied conditions.

Techno Ad takes all the relevant criteria into consideration. Do you need a recommendation on materials for a specific application? Consult with our experts today to get the right material for your needs.